- 2 Live Project

- Self-Paced/ Classroom

- Certification Pass Guaranteed

Course Offered By

Learn to operate SmartPlant 3D software clearly and confidently

Learn how to model equipment and pipes precisely

Learn to make precise and accurate construction drawings

Learn how to verify designs for errors and clashes

Adhere to industry standards such as ASME and ISO for safe designs

Be ready to work on actual EPC projects and engineering teams

Trainers with actual industry experience

Live projects within the course for effective learning

Flexible timing slots for all types of students

Recorded classes and study materials given

Placement support to get placed within short durations

Official certification upon course completion

Engineering graduates or diploma holders from the relevant streams

Working professionals and freshers willing to learn CAD and design

Basic knowledge of CAD desirable but not essential

Freshers looking for a plant design software career

Technical professionals who wish to increase their skill set

Oil & gas, petrochemical, and power generation industry jobs

Design engineer, modeler, or piping designer opportunities

International projects and nation international work opportunities

Career development to project management and consultancy positions

Industries rely increasingly on 3D software for effective plant design

Basic SP3D software introduction and setup

Equipment and piping modeling techniques

Template and style rule creation

Structural support design and detailing

Space layout management and clash detection

Isometric and spool drawing extraction

Material list and report generation

Knowledge and implementation of design standards such as ASME and API

Certificate upon completion of the entire course

Industry-approved and respected certificate

A few certificates have project or internship completion

Assists in enhancing employment opportunities and employer confidence

Technical support from well-known institutes with certification

Freshers' initial salary is between 3 to 8 lakh per annum

Mid-level engineers make 8 to 15 lakh annually

Seniors designers may make 20 lakh or more a year

Pay varies by company, location, and experience

Hands-on work and certification enhance pay potential

Begin as SP3D piping designer or 3D modeler

Promote to design engineer or project engineer

Subsequently develop into project manager or consultant positions

Master related design software for greater alternatives

Chances of working on large international projects

Hyderabad emerging as a hub for technical and engineering education

Firms need SP3D expertise for industrial applications

Flexibility of the course benefits working individuals and freshers

Live projects and expert support enhance learning

Placement assistance facilitates employer-employee connections

Create precise Model 3D piping and plant equipment

Pull out isometric and spool drawings for construction purposes

Identify and correct design clashes and errors

Coordinate with other engineering departments

Ensure all designs meet safety and quality requirements

Create detailed documentation for use in projects

Oil & gas and petrochemicals industries

Power generation and energy firms

Engineering and construction companies (EPC)

Pharmaceutical and food & beverage sectors

Offshore and marine engineering firms

Infrastructure and mega construction projects

Trainers with rich industry experience

Hands-on practice with actual project examples

Flexible timings to suit various student requirements

Quality study materials and lab assistance

Job help placement assistance

Known certification for improved jobs

we train you to get hired.

we train you to get hired.

By registering here, I agree to Croma Campus Terms & Conditions and Privacy Policy

Overview

Layout

Session Template

Session File

Options

Common Views

Zoom Tool

Window Area

Refresh View

Active View Control

Rotate View

Looking at Surface

View Format

Surface Style Rules

System

Assembly

Spatial (Volume or Planes)

Logical Permission Group

Object Types

Properties

Control Points / Notes / Hyperlink

Distance

Minimum Distance between Objects

Angle

Label Editor

Electrical System

Cableways

Cable Tray / Conduit

Cables

Branch on a Run

Intersect to Branch

Branch using Pinpoint

Selecting a Component

Reference Position

Point Along option

Selecting Different Ports / Flip

Routing Cableway

Edit Straight Features

Edit End Features

Edit Cross Sections

Conduit System

Route Options

Insert Conduit Fittings

Placing Ducts using Cableway

Selecting Equipment

Selecting Cables

Defining Properties

Selecting Cableways

Defining Exit/Entry Point

Indian Electricity Rules

National Electrical Code of India (NEC)

National Building Code of India (NBC)

Applicable Standards issued by Bureau of Indian standards (BIS)

Institute of Electrical & Electronics Engineers (IEEE)

Regulations of Local Fire Authorities

Requirements Stipulated by Pollution Control Board for Noise & Air

Control Devices

Measuring Devices

Circuit Protection Devices

Transformers

Diesel Generators

Capacitors

Bus Ducts, Bus-bars, Cables (HT/LT) & Wires

Motors & Pumps

Luminaries – General & Emergency

Isolators & Socket Outlets

UPS/Inverter & Battery Banks

Earthing or Grounding

Lightning Arrestor

Panels (LT)/Switch Board/Motor control centers (MCC’s)/Final Distribution boards (DB’s)

Cable Trays, Trunking or Raceways, Conduits & Underground Pipes (Concrete/PVC)

Lighting Load – Internal & External

Utility Power Load

HVAC Loads like FCU’s, Fans etc

PHE & FF loads like Water transfer pumps, Booster pumps, Fire Fighting pumps, Jockey pumps etc

Lifts (Elevator) Load

Computer & Data Centre (Server) Loads for Office Building

ComponentNote (Type 1 Labels)

EndConnection (Connection Note and Nozzle Note Labels)

Misc Spec labels (Pipeline Header)

Weld List Labels

DrawingFrame (Title Block Labels)

AttributeMAP

Mapping Attributes to the Border

Fixed - Style 1

Variable - Style 2

User-Defined - Style 3

Various Material List Options

Material List Labels

Using your Own Border Template

Modifying Delivered Style xml File to Match

Bulk Loading the Style

Volume Drawings

Snapshot Drawings

Manual Drafting

Overview

Layout

Session Template

Session File

Options

Common Views

Zoom Tool

Window Area

Refresh View

Active View Control

Rotate View

Looking at Surface

View Format

Surface Style Rules

System

Assembly

Spatial (Volume or Planes)

Logical Permission Group

Object Types

Properties

Control Points / Notes / Hyperlink

Distance

Minimum Distance between Objects

Angle

Label Editor

Grids

Coordinate Systems

Smart Plant Structure

Grid Wizard

Placing Coordinate System

Modifying Grids

Adding Grid Planes

Rotated Coordinate Systems

Rotated Planes

Beams

Columns

Braces

Name Rule - Naming Rule

Parent System

Type Category

Type

Priority

Continuity

Cross section

Section Standard

Section Type

Section Name

Material

Grade

Angle

Cardinal Point

Place Member Ribbon Bar

Basic Sketch 2D Overview

Draw (Sketch 2D)

Sketch Method

Select an Opening from Catalogue

Footing Ribbon Bar

Property Page

Placement

Modifications

Rule-Based Offset

Assembly Connection Ribbon Bar

Base Plate

Splice

Fitted Assembly Connection

Corner Gusset Plates

Attributes

Generic Move Command

Pin Point

Point Along Tool

Frame Connection

Coincident Plane

Offset from Plane

Angle from Plane

Point/Normal Vector

Point Plane

ComponentNote (Type 1 Labels)

EndConnection (Connection Note and Nozzle Note Labels)

Misc Spec labels (Pipeline Header)

Weld List Labels

DrawingFrame (Title Block Labels)

AttributeMAP

Mapping Attributes to the Border

Fixed - Style 1

Variable - Style 2

User-Defined - Style 3

Various Material List Options

Material List Labels

Using your Own Border Template

Modifying Delivered Style xml File to Match

Bulk Loading the Style

Volume Drawings

Snapshot Drawings

Manual Drafting

Overview

Layout

Session Template

Session File

Options

Common Views

Zoom Tool

Window Area

Refresh View

Active View Control

Rotate View

Looking at Surface

View Format

Surface Style Rules

System

Assembly

Spatial (Volume or Planes)

Logical Permission Group

Object Types

Properties

Control Points / Notes / Hyperlink

Distance

Minimum Distance between Objects

Angle

Label Editor

Pipeline

Pipe Run

Features

Parts

Port

Path Leg

Connections

Define the Pipe Run Properties

Length Control Tool

Route Pipe Run with Pin Point

Angle Control Tool

Pipe Run Smart Step Ribbon Bar

Plane Lock Options

Default Turn Options

Selecting a Turn

Select Fitter Options

Delete Pipeline

Delete Pipe Run

Delete Feature

Connecting to End Feature

Connecting to Nozzles

Branch on Pipe Run

Intersect to Branch

Selecting a Component

Reference Position

Point Along option

Selecting Different Ports / Flip

Edit Straight Features

Edit End Features

Edit Run Change Features

Editing Features

Insert Split Ribbon Bar

Flow Direction

Insulation

Relation Tab

Offset Control Tool

Component by Tag

Piping Specialty

Instruments

Slope Format

Route Sloped Run

Turn Slope Lock On/Off

Flanged Spec

Modifying Flanged Pipe

Relative Tracking Mode

Retrieving PID

Routing from PID

Comparing Data

Updating Data

Insert Tap Command

Running Reports

Setting Local IFC

Running Local IFC

Standard Parametric/Non-Parametric

Equipment Placement

Modelling of Equipment using Primitive Shape

3rd Party software – SAT format (SolidEdge v-14)

Physical, Insulation, Maintenance

Piping Port

Ducting Port

Cableway Port

Conduit Port

Cable Port

Foundation Port

Equipment from Catalogue (standard) by Shapes

Pinpoint

Locate on Display List

Locate on List Only

Select Command

Delete Command

Undo Command

Move Command

Rotate Equipment

Rotate Command

Open the Properties Page

Copy/Paste Command

Equipment From SAT File

Placing Nozzles with Graphics

Nozzles with no Graphics

Nozzles from PID

ComponentNote (Type 1 Labels)

EndConnection (Connection Note and Nozzle Note Labels)

Misc Spec labels (Pipeline Header)

Weld List Labels

DrawingFrame (Title Block Labels)

AttributeMAP

Mapping Attributes to the Border

Fixed - Style 1

Variable - Style 2

User-Defined - Style 3

Various Material List Options

Material List Labels

Using your Own Border Template

Modifying Delivered Style xml File to Match

Bulk Loading the Style

Volume Drawings

Snapshot Drawings

Manual Drafting

we train you to get hired.

Phone (For Voice Call):

+91-971 152 6942WhatsApp (For Call & Chat):

+91-971 152 6942Stories

success

inspiration

career upgrade

career upgrade

career upgrade

career upgrade

You will get certificate after

completion of program

You will get certificate after

completion of program

You will get certificate after

completion of program

in Collaboration with

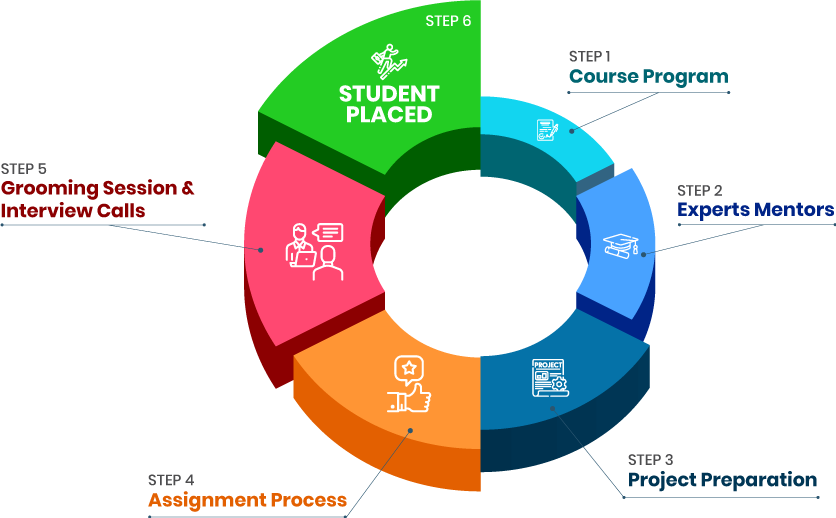

Empowering Learning Through Real Experiences and Innovation

we train you to get hired.

Phone (For Voice Call):

+91-971 152 6942WhatsApp (For Call & Chat):

+91-971 152 6942Get a peek through the entire curriculum designed that ensures Placement Guidance

Course Design By

Course Offered By

Ready to streamline Your Process? Submit Your batch request today!

No, the course begins with fundamental topics, so you don't require pre-existing CAD knowledge.

You primarily learn SmartPlant 3D software for plant and 3D piping design.

Yes, engineering freshers such as mechanical and civil can join.

Placement assistance is provided by most institutes to get you jobs.

You can grow into a piping designer, SP3D modeler, or design engineer in most industries.

Highest Salary Offered

Average Salary Hike

Placed in MNC’s

Year’s in Training

fast-tracked into managerial careers.

Get inspired by their progress in the

Career Growth Report.

FOR QUERIES, FEEDBACK OR ASSISTANCE

Best of support with us

For Voice Call

+91-971 152 6942For Whatsapp Call & Chat

+91-9711526942