Course Design By

Nasscom & Wipro

+ More Lessons

Course Design By

Nasscom & Wipro

Course Offered By

Croma Campus

Stories

success

inspiration

career upgrade

career upgrade

career upgrade

career upgrade

21-Feb-2026*

23-Feb-2026*

18-Feb-2026*

21-Feb-2026*

23-Feb-2026*

18-Feb-2026*

You will get certificate after

completion of program

You will get certificate after

completion of program

You will get certificate after

completion of program

in Collaboration with

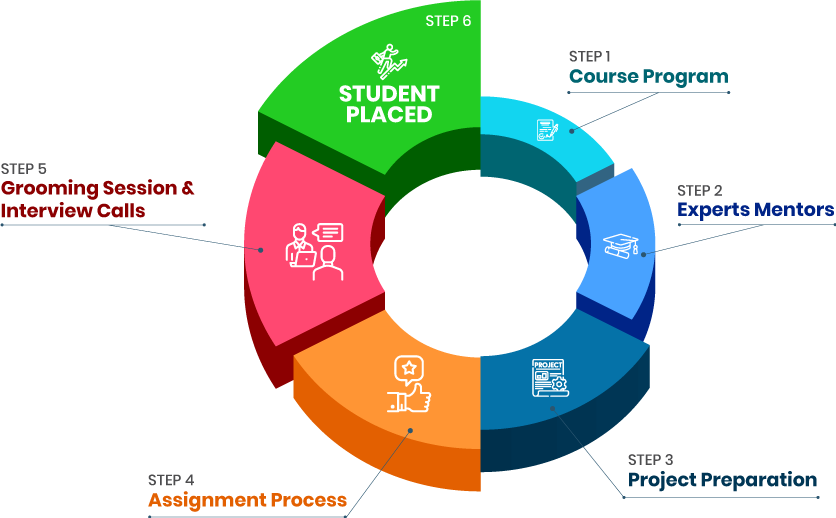

Empowering Learning Through Real Experiences and Innovation

we train you to get hired.

Phone (For Voice Call):

+91-971 152 6942WhatsApp (For Call & Chat):

+91-971 152 6942Get a peek through the entire curriculum designed that ensures Placement Guidance

Course Design By

Course Offered By

Ready to streamline Your Process? Submit Your batch request today!

Highest Salary Offered

Average Salary Hike

Placed in MNC’s

Year’s in Training

fast-tracked into managerial careers.

Get inspired by their progress in the

Career Growth Report.

FOR QUERIES, FEEDBACK OR ASSISTANCE

Best of support with us

For Voice Call

+91-971 152 6942For Whatsapp Call & Chat

+91-9711526942